Angsana Tunas Sdn Bhd was incorporated on 24th January 2002 as an engineering construction & investment company. Throughout the years, we have been constantly growing and our expertise is in project management, design, and engineering. The industries which we cover include architectural finishes & hard landscape, facade engineering, architectural & structural steel, fuel system, and telecommunication. Operating from the modest factory in Kg Baru Subang situated close to the Subang Airport, we have to date successfully completed a significant number of projects in the construction field. Supported by a team of dedicated and supportive professionals with a wide range of experiences, we have demonstrated our understanding of the demands of the construction business. Our track records have also proven our endless pursuit for excellence through the completion of projects on time with strict quality & cost control, management & client interaction.

Who Are We

About Us

Our History

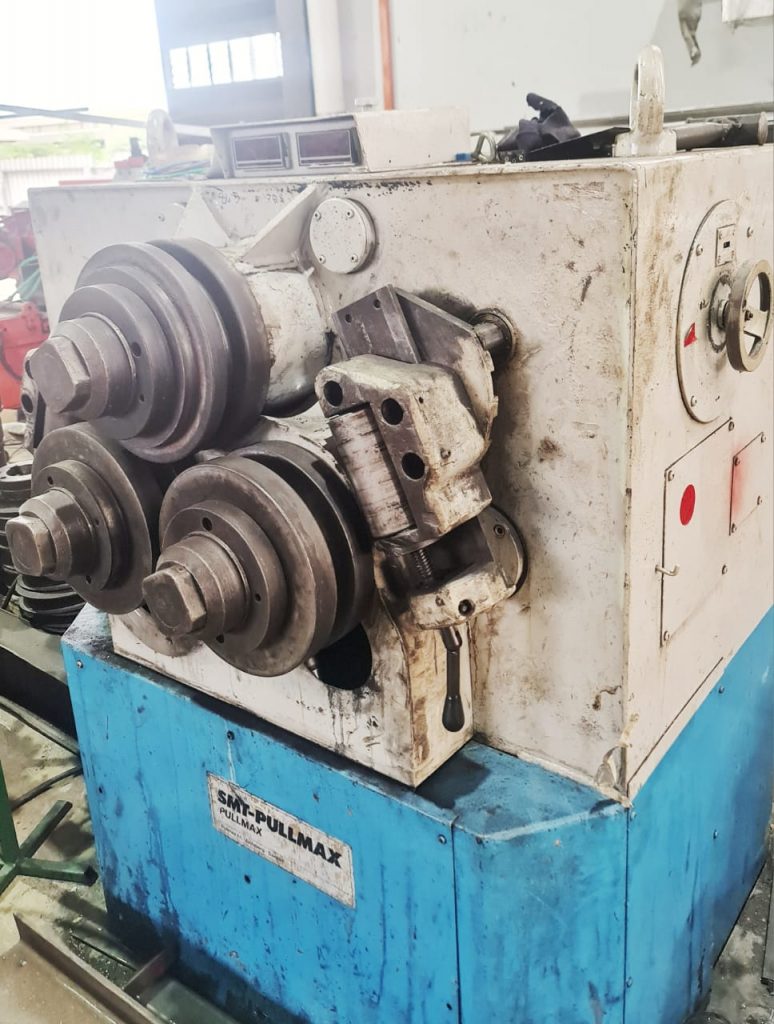

ANGSANA TUNAS SDN BHD was founded by Mr. Kester Boon in 2002. At that time, Malaysia was experiencing a rapid transition from 2G to 3G network, and the demand for specialist contractors to keep up with the pace of infrastructure development set by the local telco service providers was strong. Mr. Kester Boon recognized the potential business opportunities and with a clear direction in mind, he started the business with a rented 500 sqft. office at Desa Petaling. A year later, we moved to Kg Baru Sg Buloh with a 7,000 sqft. factory attached to our office and started providing telco-related engineering services and steel structures fabrication works to ride with the business trend. Our operations were moved to Kg Baru Subang in 2008 and the rented office and factory were our home for the next 4 years.

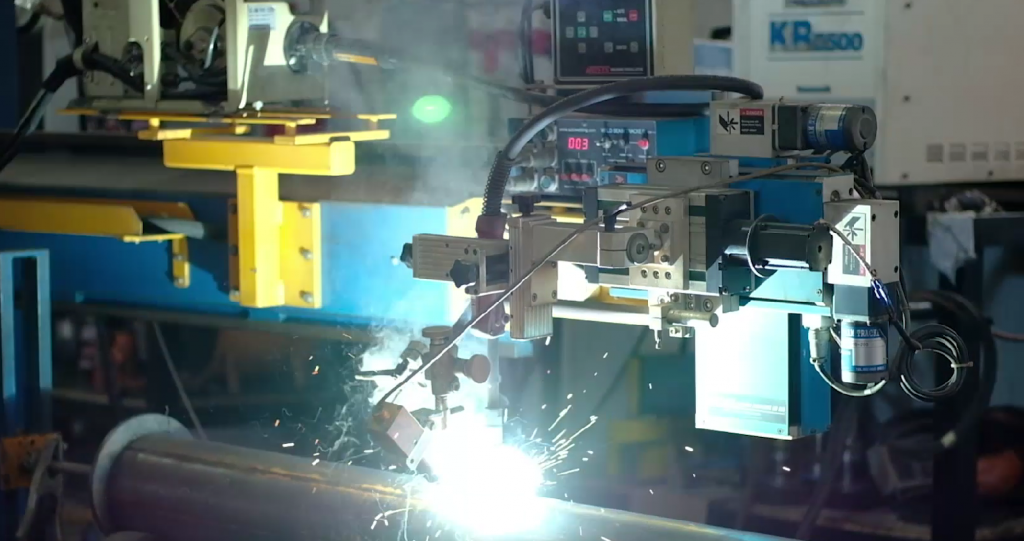

Upon building a strong business foundation, Mr. Kester Boon decided to expand the company and in 2011, we successfully built our own office, factory & warehouse with a built-up area of approximately 37,600 sqft. to meet the steady business demand as a result of the transition from 3G to 4G network.

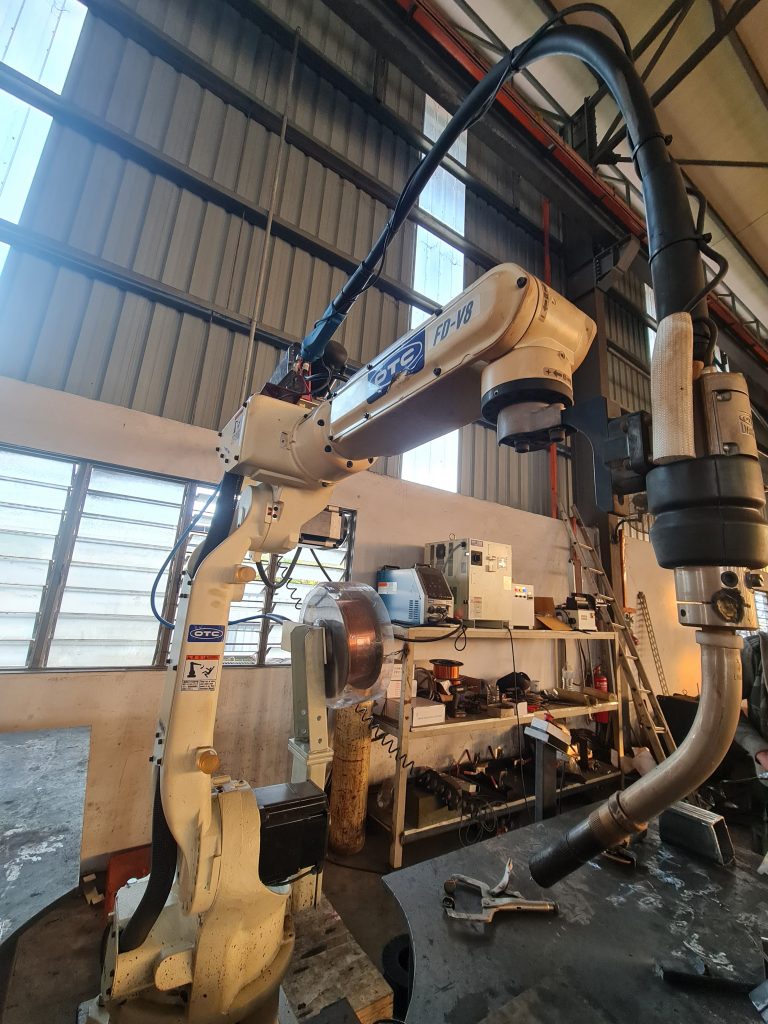

After striving in the telco industry for more than 10 years, Mr. Kester Boon felt it was time for diversification and our business weightage was gradually skewed towards the construction industry as we moved to our 5th office in 2015 since mega infrastructure projects were booming. With a strong steel fabrication background, we managed to get involved in the LRT and MRT projects.

Over the years, we manage to build a strong reputation for high-quality products & services, and our rapport developed with high-profile clients such as ZTE Corp (M), Maxis, Digi, China State Construction Engineering (M), and MMC-Gamuda enables us to continuously undertake complex and challenging projects.

In 2018, we moved to our 6th office in Kg Baru Subang with a built-up area of 42,000 sqft and operate till today. To date, our business coverage revolves around structural & architectural steel, building facades, landscaping work, fuel stations, and telco. It has been 20 solid years since we first opened our doors and we certainly look forward to better years ahead.

Our Goals

Our Mission

To provide a nurturing working environment that cultivates our committed team members to always strive for improvement and to build and maintain lasting relationships with our valued partners and customers through quality deliveries of products and services.

Our Vision

To be a highly recognized and progressive construction company that delivers products and services with strict time & cost control and first-rate quality.

Founder’s Statement

ANGSANA TUNAS SDN BHD has been experiencing steady growth since we opened our doors in 2002. We are indeed pleased with the healthy book orders and profitability performances, as they are reflective of the commitment and direction of vision that the company embraces.

Despite having to experience the global financial crisis in 2008, the construction sector downtrend period, and ongoing economic recession due to the Covid-19 pandemic, we manage to stand strong and achieve sustained growth through essential measures undertaken to ensure the stability of our finances and business operations. Looking ahead, we are foreseeing lights at the end of the tunnel and we are positive about our prospects and future outlook as when the pandemic has been stabilized, containment measures lifted, borders reopened and the industry is in full swing again, our upcoming projects are going to inject doses of excitement.

We will continue to explore and venture into projects which offer more sustainable, capital-efficient, and profitable growth aligned with our vision and missions. Our emphasis on quality deliveries is depicted in our strict cost & time control, fabrication with high accuracy & quality control as we strive to offer top-notch products and services to all our customers.

In the long run, we set our sights on expanding and secure more projects at other states in Malaysia and mark footprints in the international market. This will be an ultimate challenge to us to constantly improve and expand our horizon into the international markets to serve and meet the ever-changing demands and requirements of our customers from all over the world. More importantly, we are looking at building and maintaining a positive long-term relationship with our clients. At present, we have a good business relationship with a number of multinational companies and this will definitely serve as a foundation for Angsana Tunas Sdn Bhd towards achieving our vision in the near future. With our vast and valuable experience in this industry, coupled with our profound reputation in the Malaysian market, we believe our vision is within reach.